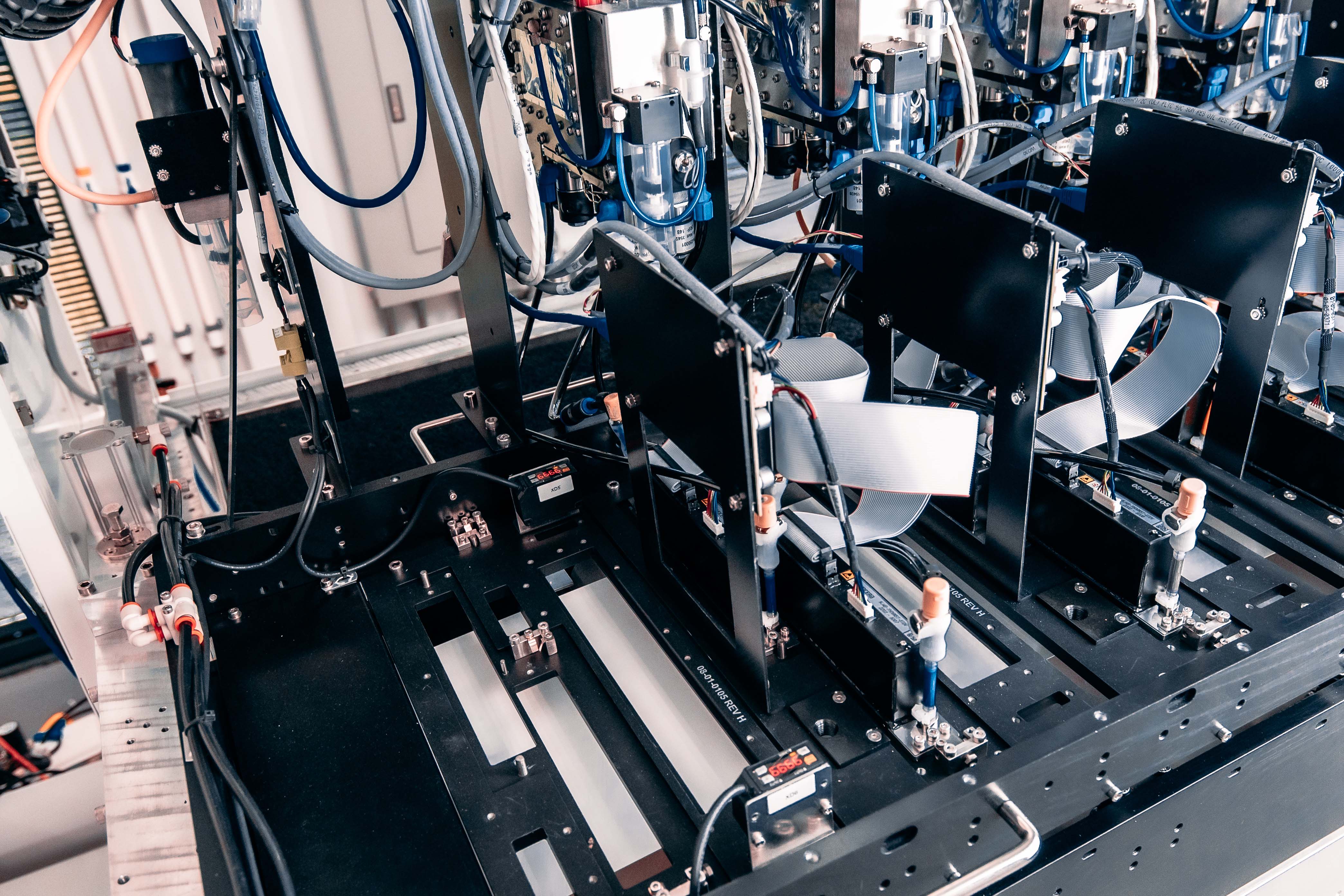

Water-Based Inkjet Engine

3800 Series WB – Retrofit

3800 Series WB – Retrofit

The water-based print engine is designed for integration onto existing flexo presses and converting equipment. Digitally print on labels, flexible film packaging and other porous or non-porous substrates.

Download BrochureYou can significantly reduce your capital investment and get into digital and hybrid printing with a Colordyne Inkjet engine, rather than investing in a standalone digital press.

You don't need to worry about having to reinvest in new tooling. Keep utilizing all of your dyes and press-converting accessories.

Retrofitting a Colordyne inkjet doesn't reduce any of the functionality of your existing press. You'll be able to leverage digital, run flexo, or combine both for hybrid label production.

By retrofitting an inkjet engine you can prime, digital print, varnish, laminate, and die cut all in one single pass, saving you time and money.

Colordyne's approach to hybrid allows you to register every flexo station on the press, allowing for simple or complex printing applications.

Your operator already knows this press like the back of their hand. That knowledge remains relevant with the addition of a Colordyne inkjet engine.

The 3800 Series WB leverages Kao’s LUNAJET proprietary nanodispersion ink technology which increases pigment concentration so the ink can spread evenly over the surface.